How-To Videos & Instruction

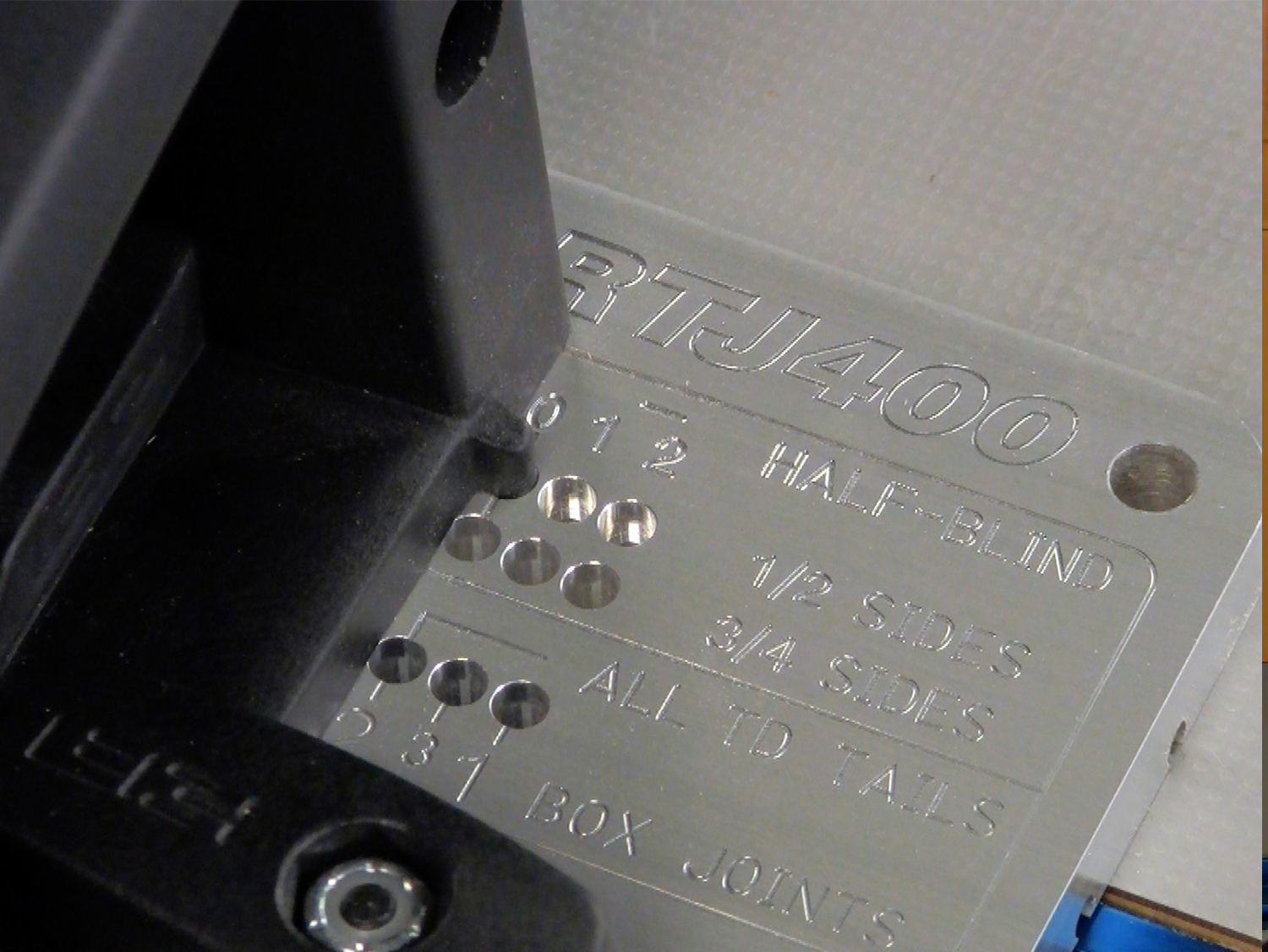

Half-blind dovetails are quick to rout on the RTJ400, because one corner (both the pins and tails) are routed in a single pass. These joints are very strong due to all the glue surfaces, and for that reason are most often used for drawers, but are also great for box and carcass construction.

1 Position the frame on the template in the half-blind mode, in either the 1/2” or 3/4” sides hole, depending on the thickness of your drawer sides. Other thicknesses can also be routed.

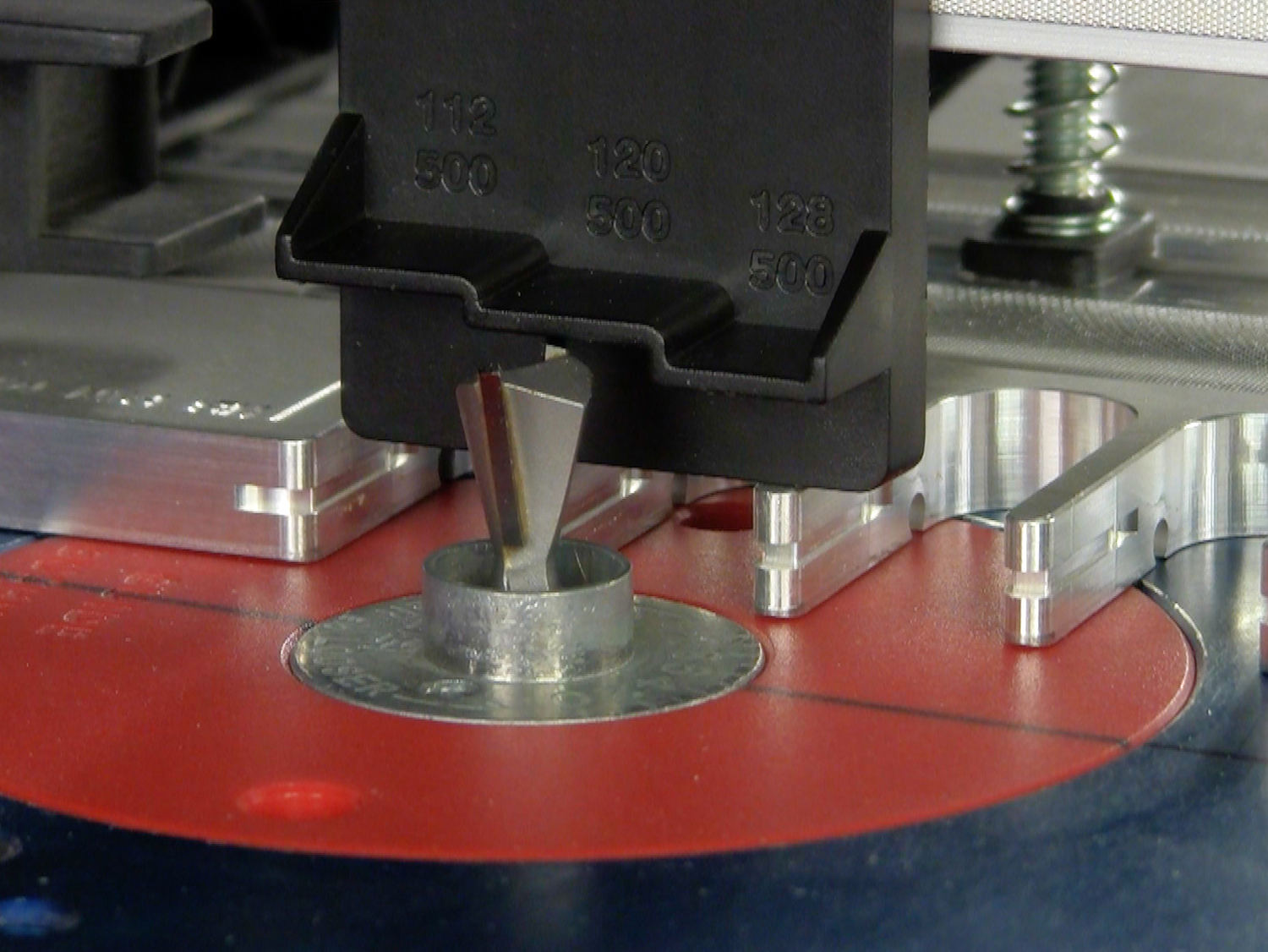

2 Use the supplied Leigh e10 guide bushing (eBush) installed in your router table and the included half-blind bit 120-500. Two other optional bits are also available.

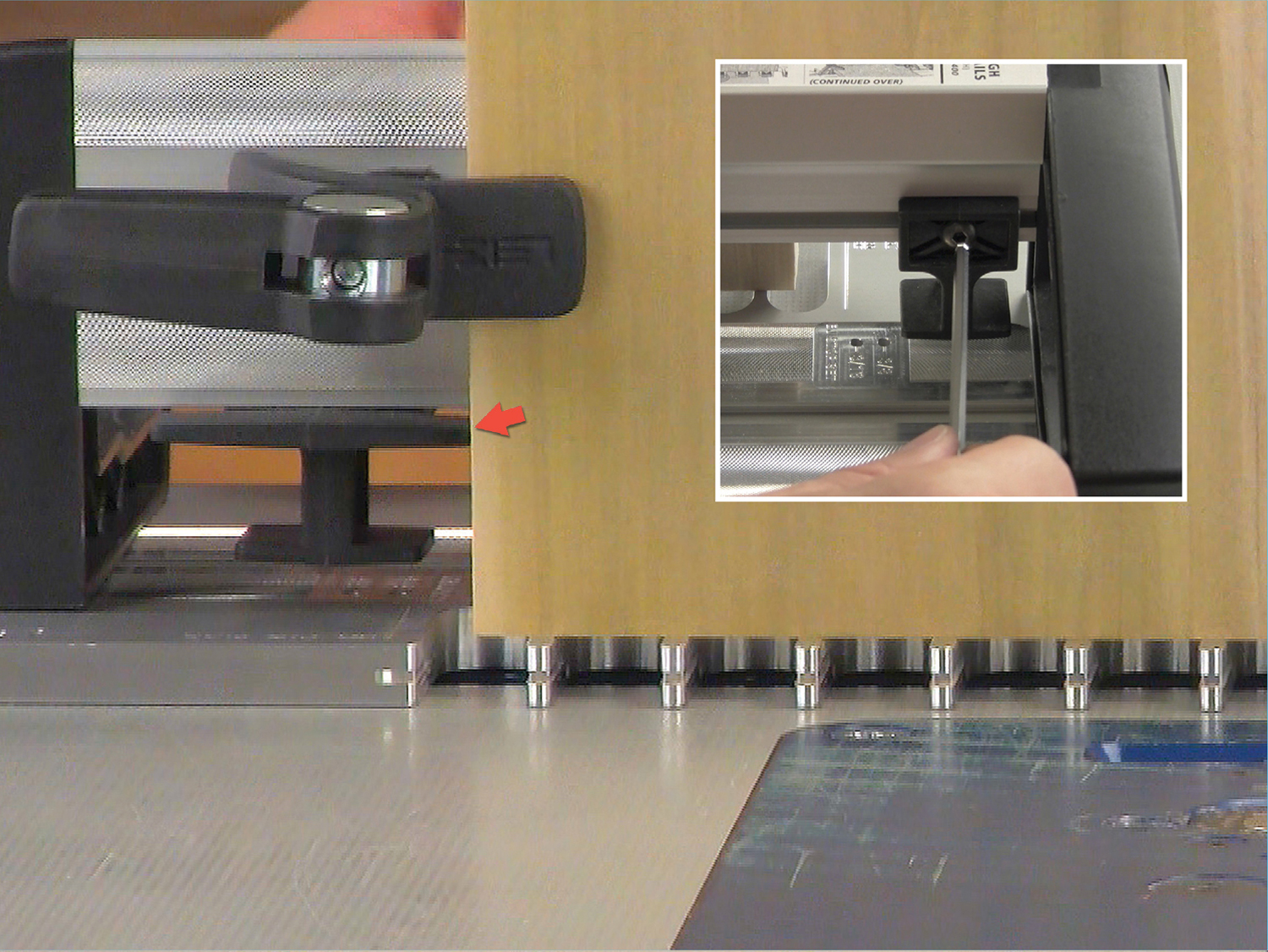

3 With the bit depth gauge clamped in the jig, raise the bit to the touch the corresponding stop.

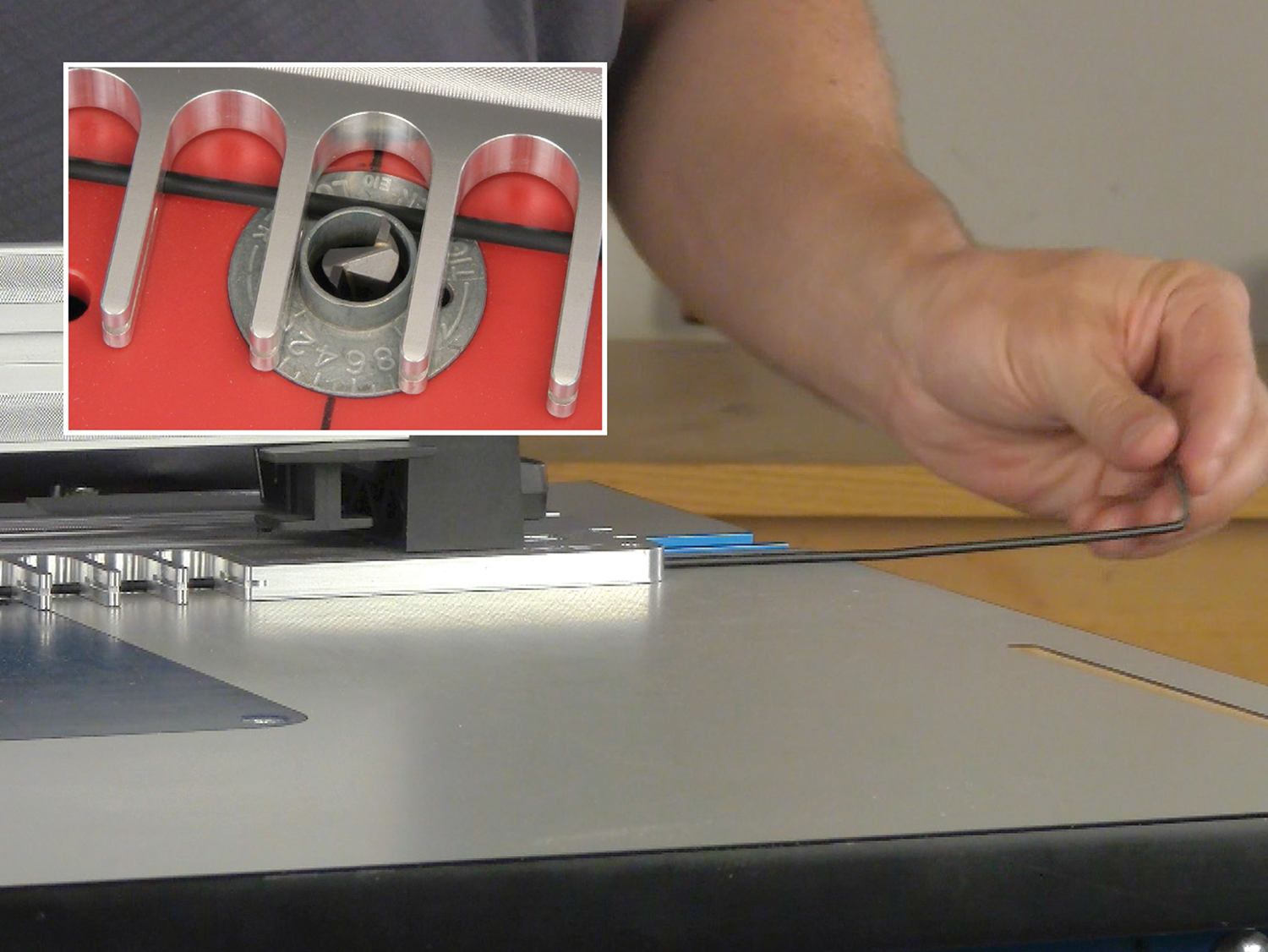

4 For drawer sides, 7/16”(11mm) to 5/8”(16mm) thick, install the stop rod. This limits the travel of the eBush in the openings, ensuring correct socket depth in the pin board.

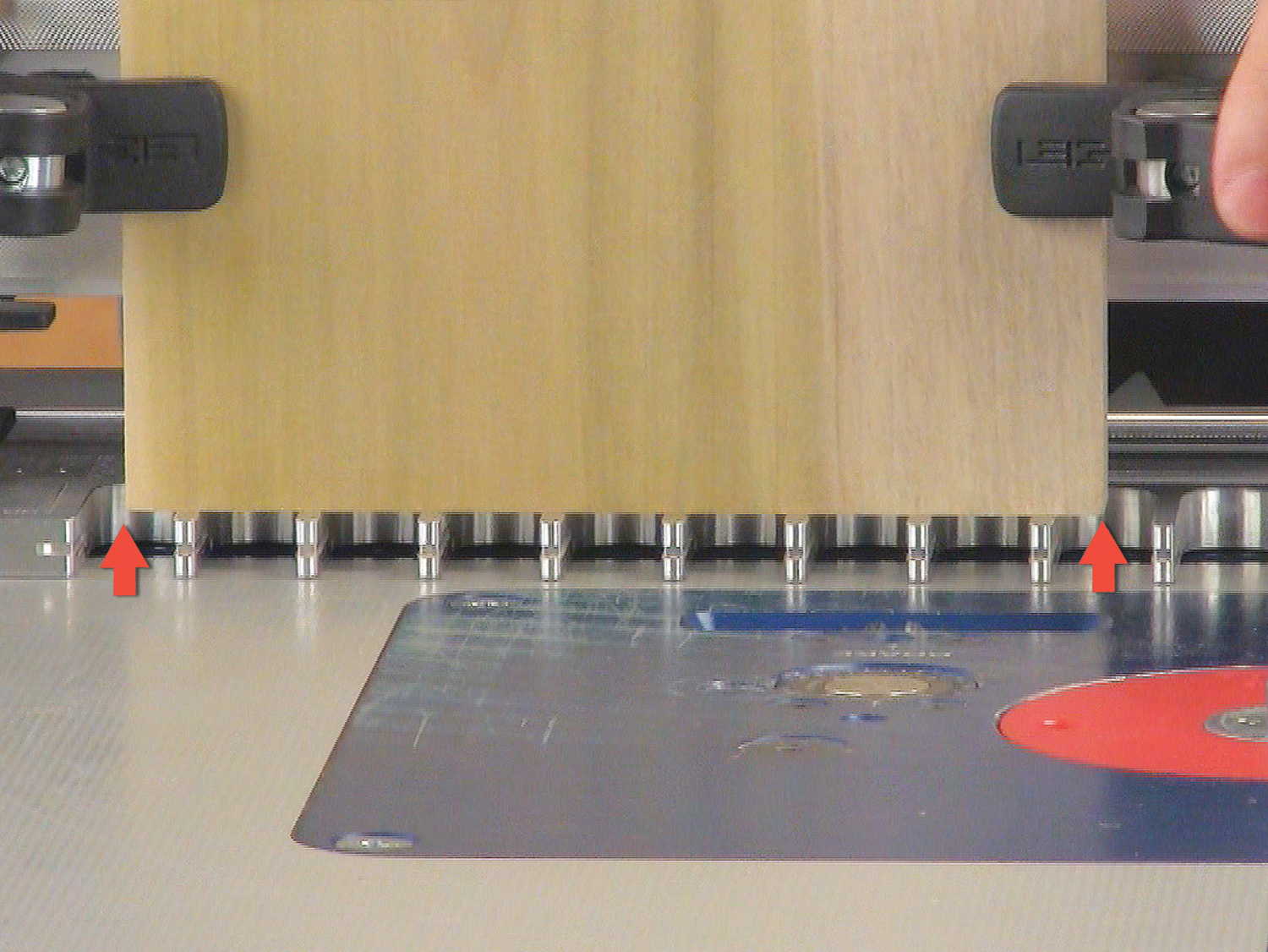

5 Center the tail board on the template.

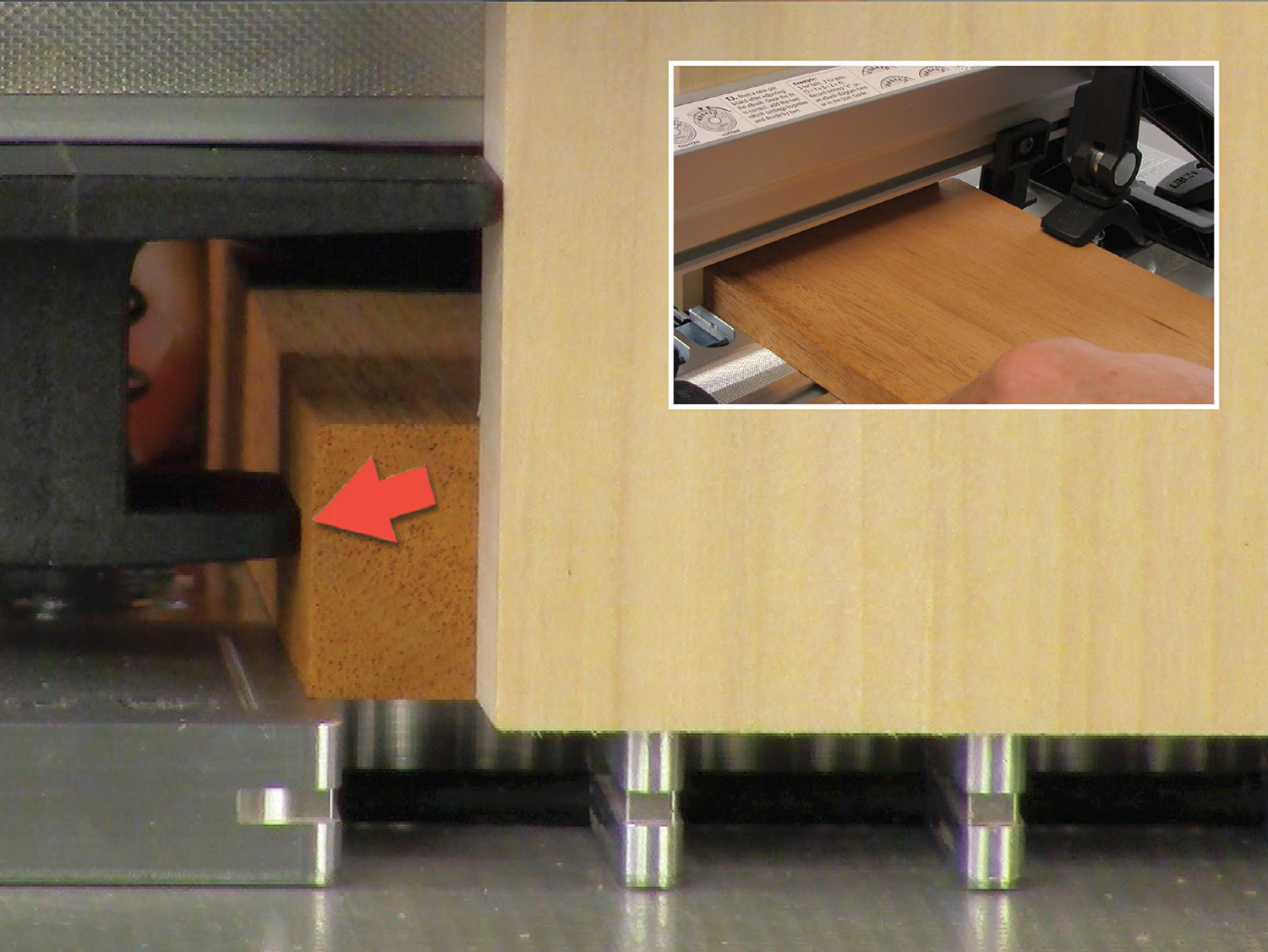

6 Set the sidestop to the board edge.

7 Clamp the horizontal pin board against the built-in offset of the sidestop. This guarantees perfect joint alignment.

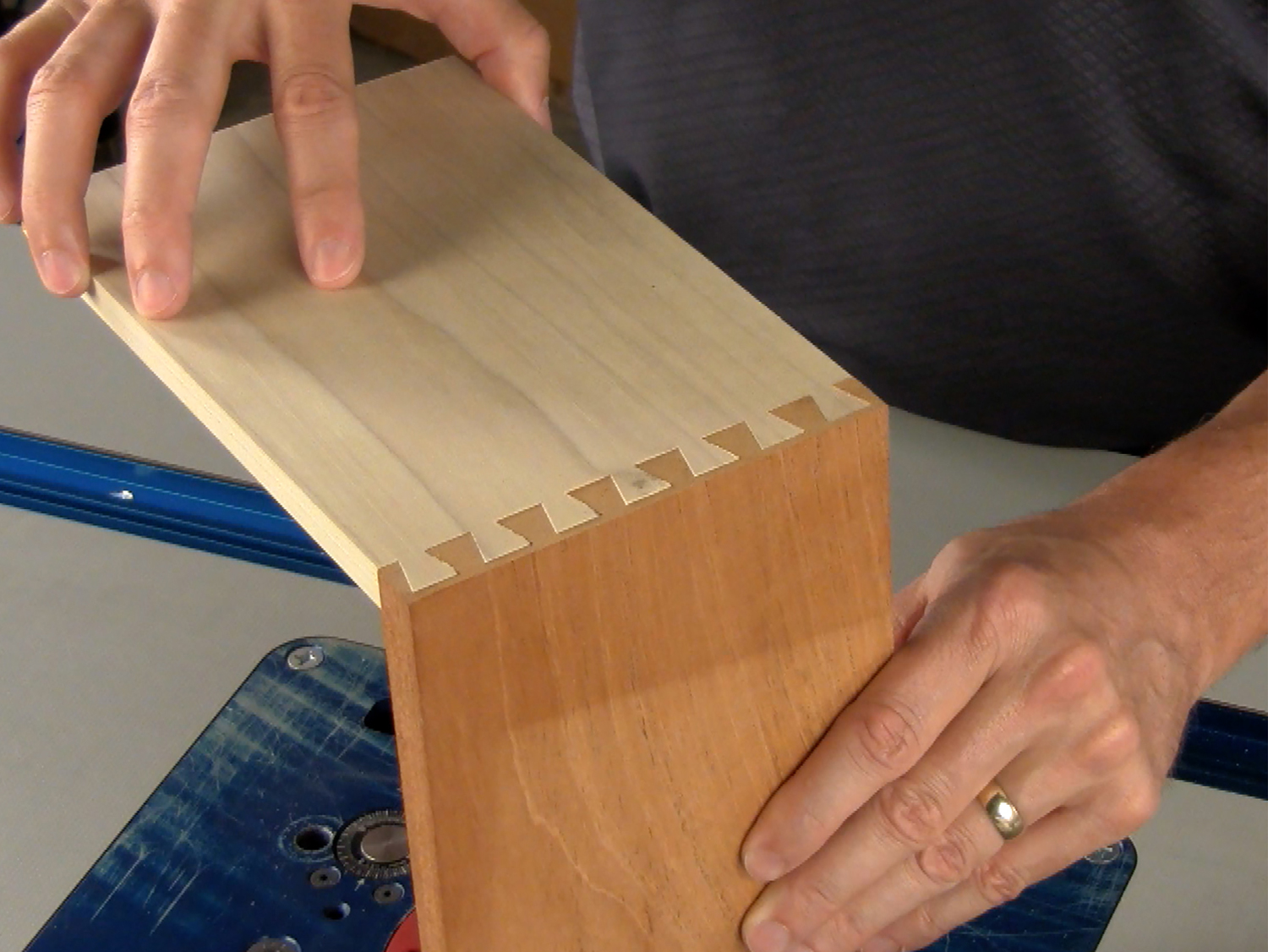

8 Rout in and out of all the template openings to form the pins, tails and sockets in a single pass.

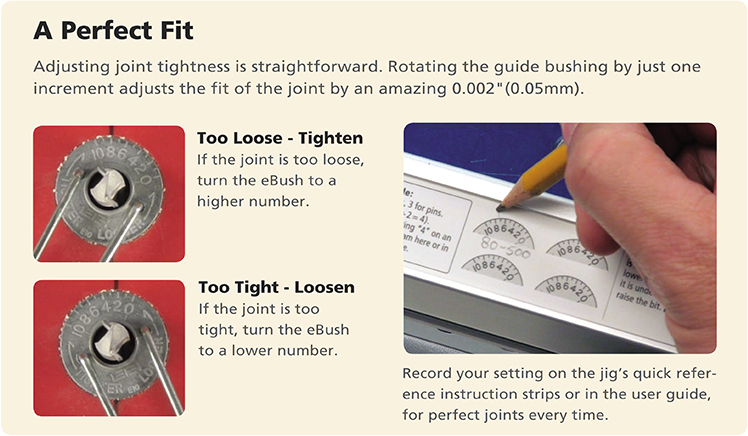

9 Fit the boards together to test the fit.

10 Joint tightness adjustment is made with the elliptical guide bushing (see ‘A Perfect Fit’ below).

For more detailed instructions, see the User Guides and Bulletins on the Support page.