How-To Videos & Instruction

Perhaps the most common use of the half-blind dovetail joint is drawer box construction. The half-blind joint shows the pins and tails on only one side of the joint while remaining completely invisible on the other. Joining drawer sides to drawer fronts using the half-blind dovetail leaves the front of the drawer without visible joinery while providing great interlocking strength opposing the stresses constantly applied to the drawer when opening and closing. The half-blind dovetail can be made with flush sides, rabbeted sides or in an asymmetric configuration.

Here’s How

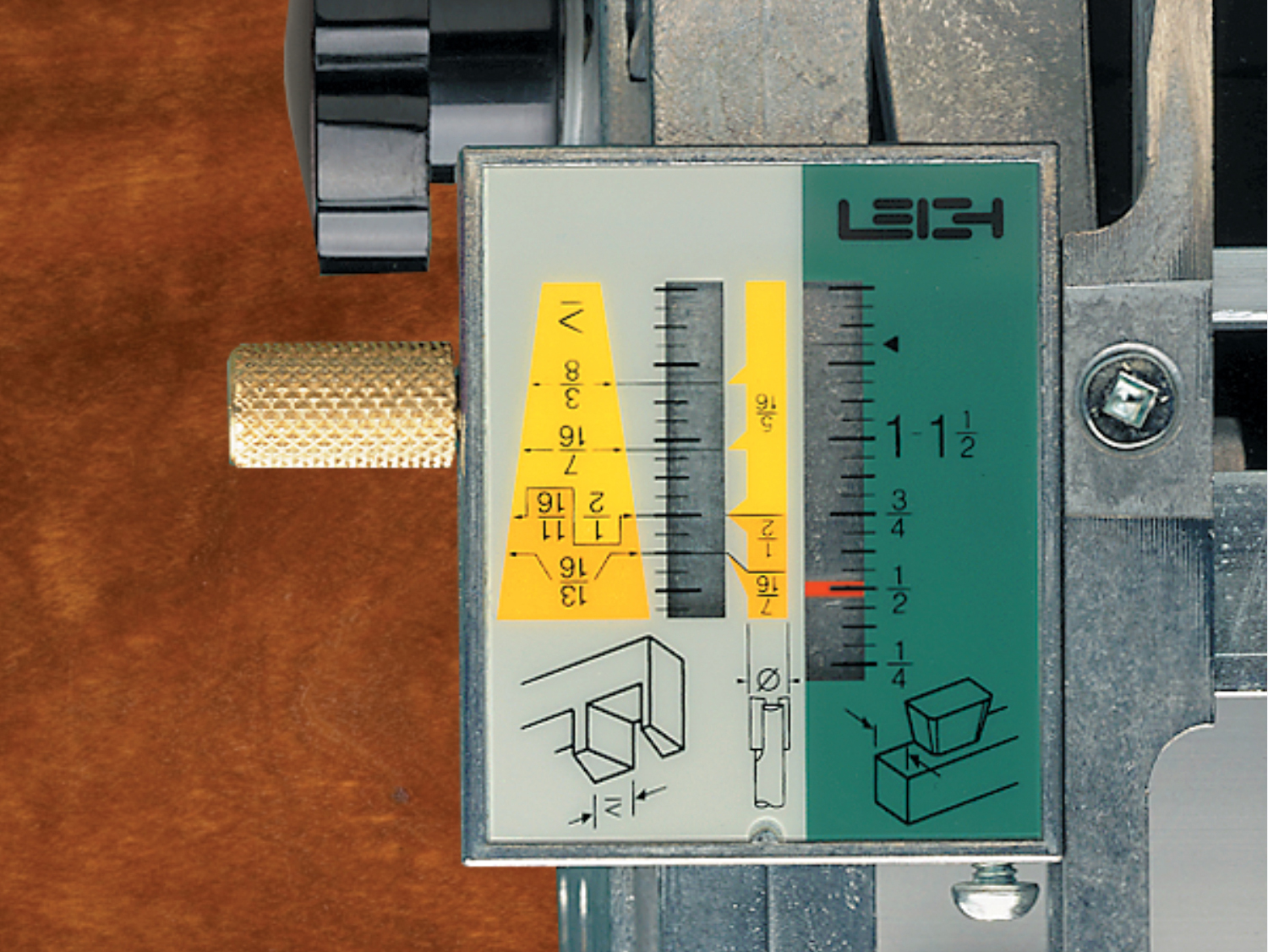

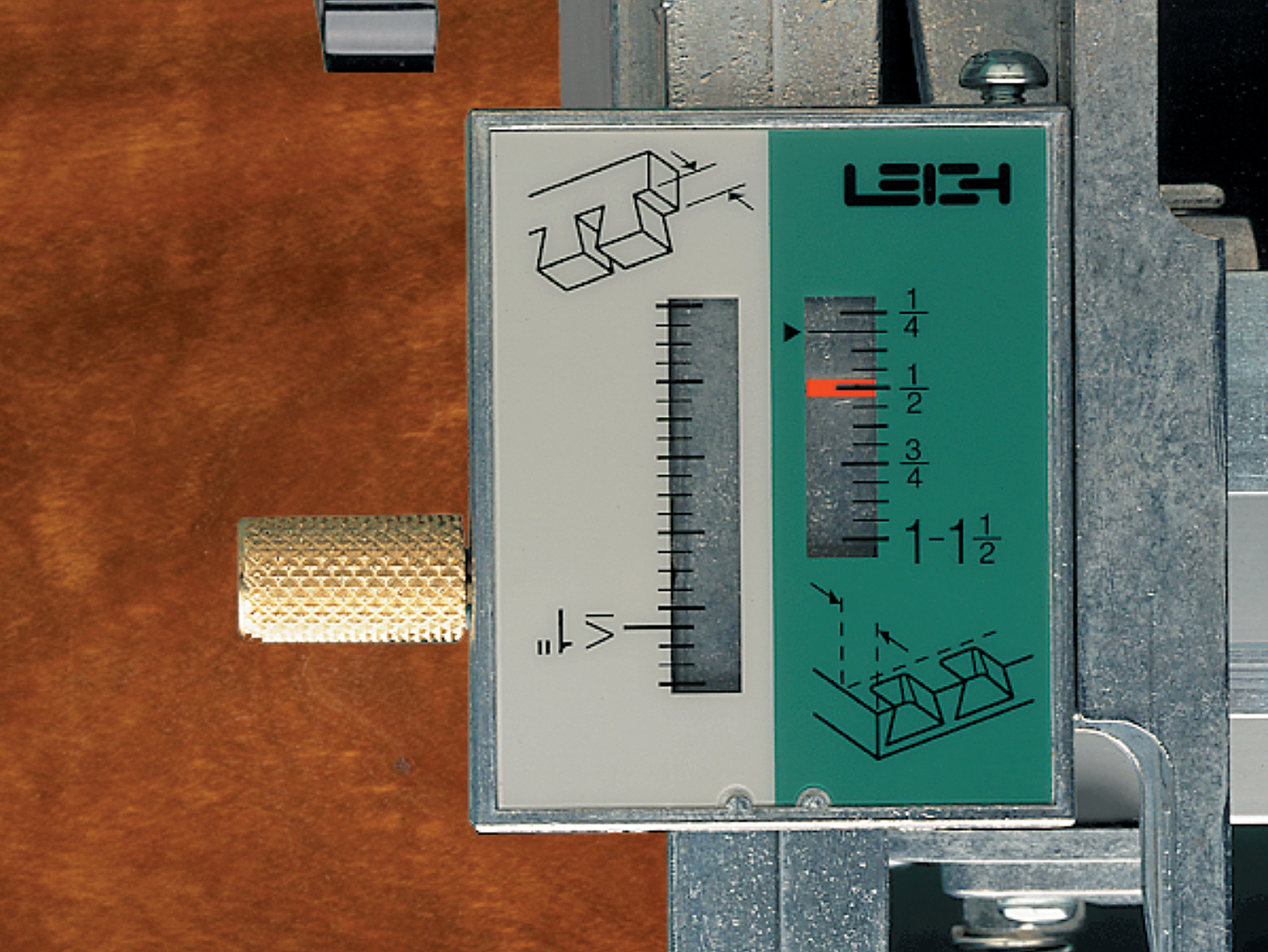

1 With the finger assembly in the half-blind tail mode, set the scale to the thickness of your tail board (drawer side). The readable area of the scale is always to the right, and is colour coded green for half-blind dovetails. An icon identifies the joint type.

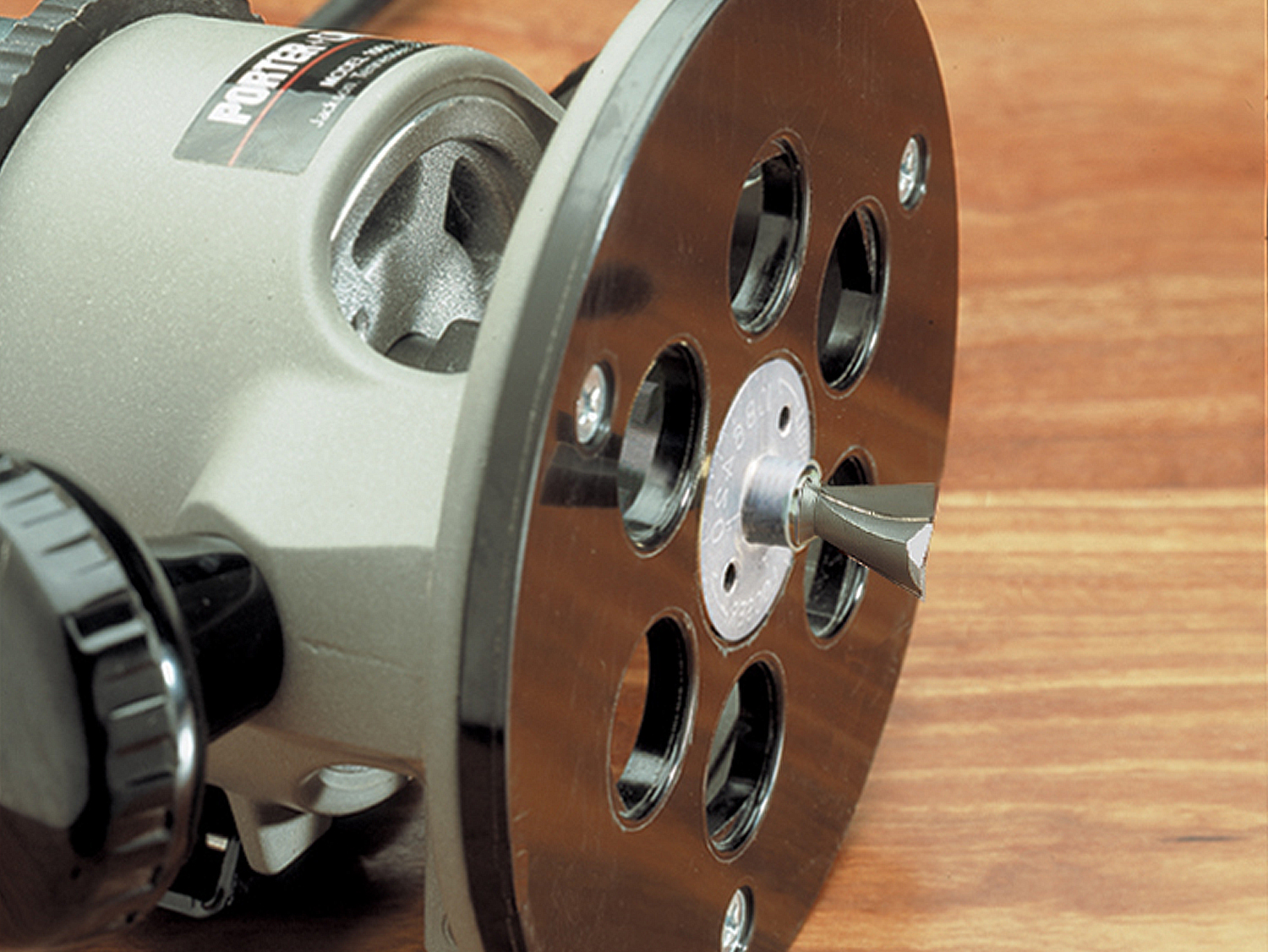

2 Use the supplied Leigh e7 guide bushing with your router and one of two supplied half-blind bits. Three other optional bits are also available.

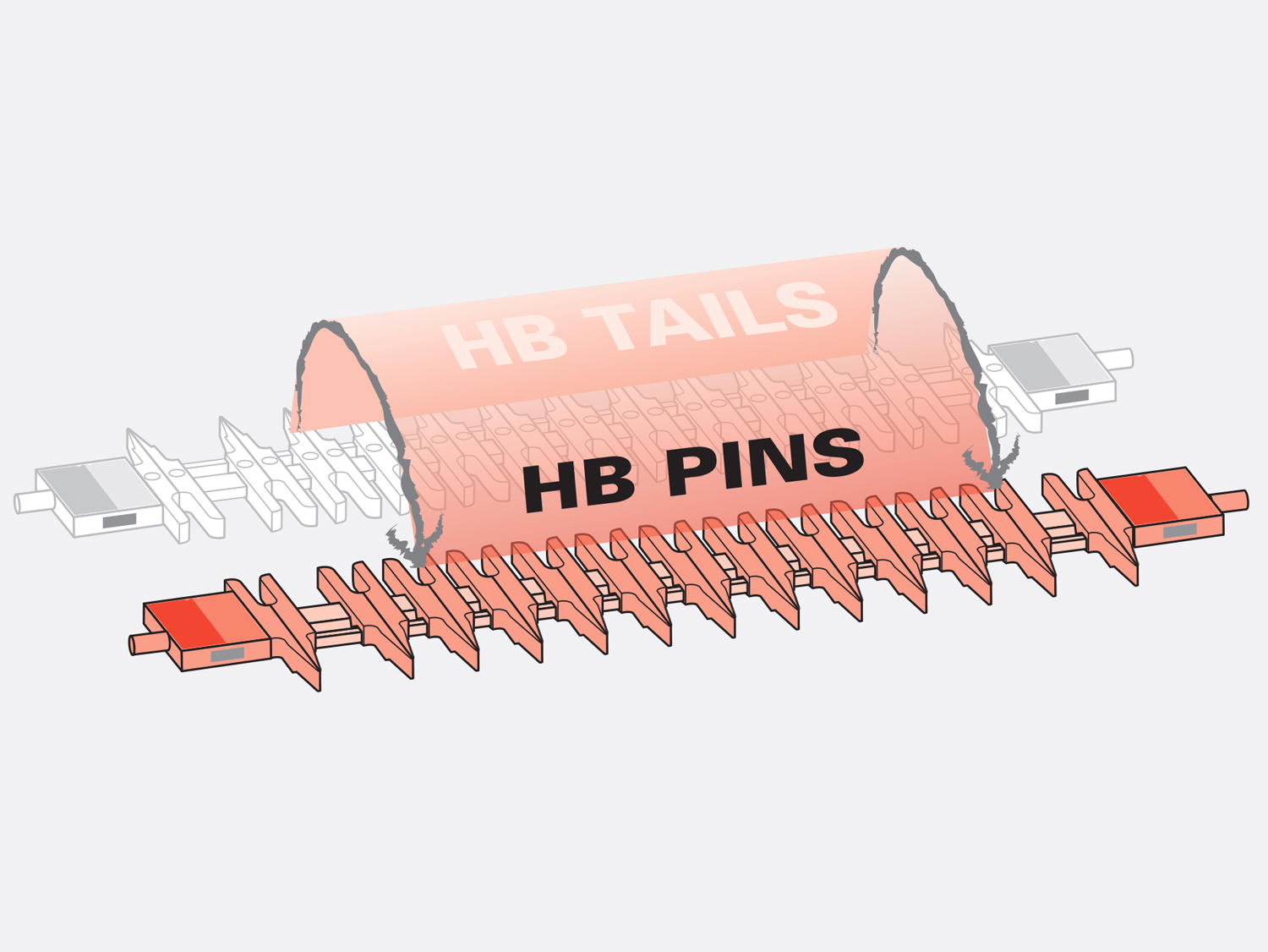

3 Arrange the guide fingers to suit the design of the project. Guide finger spacing is infinitely variable. With only one setup required, perfect tail and pin alignment is guaranteed. Wider tails are bridged with the supplied material. Rout the tails.

4 Flip the finger assembly over to access the half-blind pins mode (drawer front).

5 Again, set the scales to the thickness of your tail board (drawer side).

6 With the drawer front clamped under the finger assembly and against the sidestop, rout the pins.

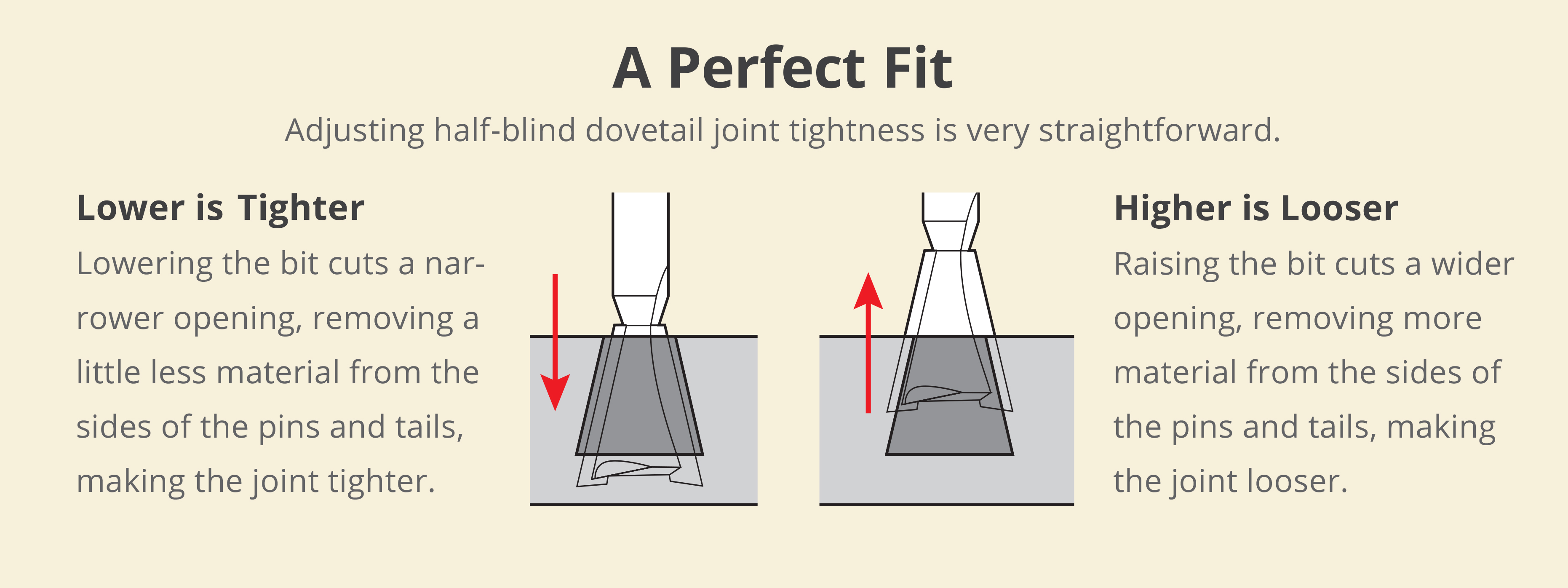

7 Fit the boards together to check the joint fit.